How to Optimize Your Manufacturing Process with Robotics

I. Introduction

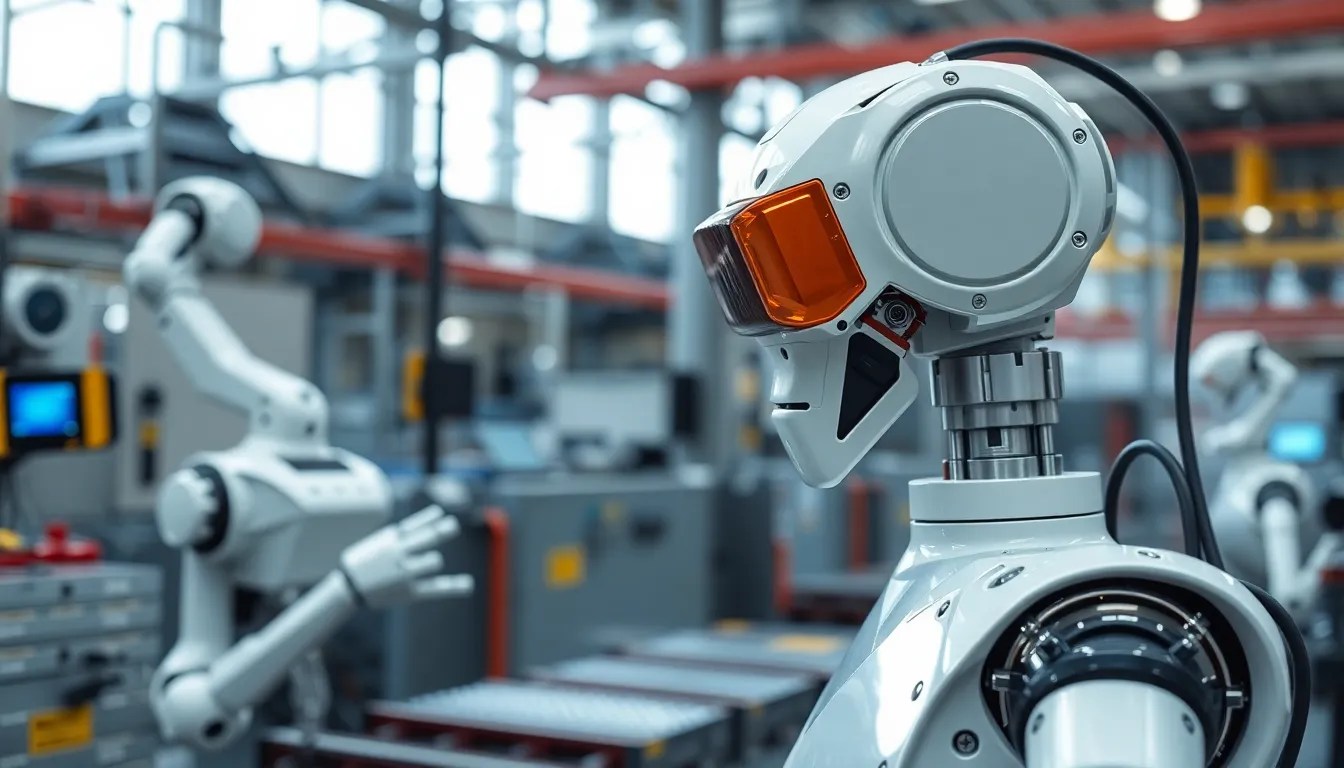

In today’s fast-paced industrial landscape, the optimization of manufacturing processes has become a critical component for maintaining competitiveness and enhancing productivity. As industries strive for greater efficiency, the integration of advanced technology has emerged as a key strategy. Among these technologies, robotics stands out as a transformative force that is reshaping the manufacturing sector.

This article aims to explore how robotics can optimize manufacturing processes, discussing the evolution of robotics in the industry, its benefits, types of robots, integration strategies, challenges faced, and real-world case studies of successful implementations.

II. The Evolution of Robotics in Manufacturing

The journey of robotics in manufacturing dates back several decades, with significant milestones marking its evolution:

- Historical Perspective: The first industrial robots were introduced in the 1960s, primarily for tasks such as welding and material handling. These early robots were limited in functionality and required extensive programming.

- Key Technological Advancements: Over the years, advancements in artificial intelligence, machine learning, and sensor technology have significantly enhanced robotic capabilities, allowing for greater flexibility and adaptability.

- Current Trends: Today, the industry is witnessing a rise in collaborative robots (cobots) that work alongside human operators, as well as increased adoption of autonomous systems such as automated guided vehicles (AGVs).

- Future Prospects: Looking ahead, the integration of robotics with Internet of Things (IoT) technology and smart manufacturing will further revolutionize the industry.

III. Benefits of Implementing Robotics in Manufacturing

The implementation of robotics in manufacturing offers numerous advantages that can lead to significant improvements:

- Increased Efficiency and Productivity: Robots can operate continuously without breaks, leading to higher output rates and the ability to meet increasing demand.

- Improved Precision and Quality Control: Robotics ensure consistent quality by minimizing human error and maintaining high standards in repetitive tasks.

- Enhanced Worker Safety and Reduced Labor Costs: By taking over dangerous and physically demanding tasks, robots improve workplace safety and allow human workers to focus on more complex and value-added activities.

IV. Types of Robotics Used in Manufacturing

Various types of robots are utilized in manufacturing, each serving unique purposes:

- Industrial Robots: These are traditional robots used for tasks such as welding, painting, and assembly.

- Collaborative Robots (Cobots): Designed to work alongside humans, cobots enhance productivity by assisting with tasks that require both human and robotic input.

- Automated Guided Vehicles (AGVs): AGVs are used for material transport within manufacturing facilities, improving logistics and reducing handling time.

- Drones and Advanced Robotics: Emerging technologies such as drones are being utilized for inventory management, inspection, and monitoring purposes.

V. Integrating Robotics into Existing Manufacturing Processes

Integrating robotics into existing manufacturing workflows requires careful planning and execution:

- Assessing Current Manufacturing Workflows: Analyze the existing processes to identify inefficiencies and areas that could benefit from automation.

- Identifying Areas for Robotic Implementation: Focus on repetitive, hazardous, or time-consuming tasks as potential candidates for robotic solutions.

- Planning and Execution of Integration Strategies: Develop a comprehensive plan that addresses the technical and operational aspects of integration.

- Ensuring Minimal Disruption During Transition: Implement a phased approach to integration that minimizes downtime and allows for adjustment periods.

VI. Overcoming Challenges in Robotics Implementation

Despite the benefits, manufacturers may face several challenges when implementing robotics:

- Addressing Workforce Concerns and Resistance: Engage with employees early in the process, providing training and education to alleviate fears about job displacement.

- Navigating the Costs of Robotic Systems: Understand the total cost of ownership, including initial investment, maintenance, and potential savings over time.

- Technical Challenges and Solutions: Collaborate with technology providers to address integration and technical issues, ensuring a smooth transition to robotic systems.

VII. Case Studies: Successful Robotics Implementation in Manufacturing

Real-world examples illustrate the successful application of robotics in various sectors:

- Example 1: Automotive Industry: Companies like Toyota have implemented robotic systems for assembly lines, significantly enhancing production efficiency and quality.

- Example 2: Electronics Manufacturing: Firms such as Foxconn utilize robotics for precision assembly and testing, reducing cycle times and improving product quality.

- Example 3: Food and Beverage Sector: Companies like Nestlé have adopted robotics for packaging and palletizing, improving throughput while ensuring hygienic conditions.

VIII. Conclusion and Future Outlook

In conclusion, the integration of robotics into manufacturing processes is no longer a novelty but a necessity for companies looking to optimize their operations. The benefits of increased efficiency, enhanced quality, and improved safety make a compelling case for investment in robotic technologies.

As we look to the future, trends such as greater collaboration between humans and robots, advancements in artificial intelligence, and the rise of smart manufacturing will continue to shape the industry. Manufacturers should embrace robotics not just as a tool for improvement, but as a critical component of their competitive strategy in a rapidly evolving marketplace.

Now is the time for manufacturers to explore the potential of robotics and take proactive steps towards implementation to secure their position in the future of manufacturing.